DESIGN SERVICE

We provide a comprehensive range and depth of R&D, design, and manufacturing services. From front-end R&D and design, including product conceptual design, modeling design, optical design, mechanism design, electronic circuit design verification, software and hardware integration verification, prototype production, mold development, injection molding, product assembly, and product reliability testing, etc., For back-end manufacturing and production, this is our full service. It provides customers with complete solutions and complete services to meet customers’ needs for product development, design, and manufacturing continuity.

LENS DESIGN

For customers with existing product plans, we provide the most suitable specification recommendations based on customer expectations, and seek feasible solutions based on customer expectations to achieve high quality and cost reduction goals, provide a full range of services, flexible communication, and diversified features.

Our projector has the following effects:

All light source designs are designed in accordance with the effect you need and the brightness of the light source and comply with legal regulations to achieve the best brightness effect.

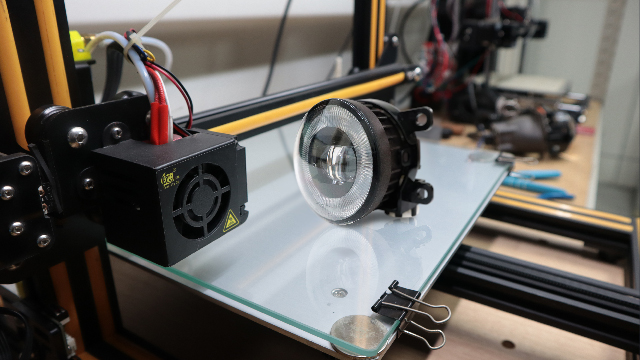

FOG LIGHTS DESIGN

Fog lights are most commonly used in rainy and foggy days. Our WS ultra-wide-angle LED projector lens fog lights to have a strong penetrating power. The wide-angle range reaches 140 degrees, which helps maintain a clear line of sight on both sides of the road. In addition, with the characteristics of the LED light source, the brightness is more uniform, and it is not easy to cause accidents due to poor weather sight. The fog lights we designed have the dual effects of fog lights and fish eyes, no matter how difficult the climate is, it can still make the road ahead bright.

With the dual effect of fog lights and fish eyes, it can have the most comfortable and safe driving environment in rain and fog.

“One light for four purposes” it has the function of daytime running lights, can improve the safety of driving during the day, and has a super wide-angle effect, so that you can have better lighting when driving in the dark night without any street lights or rain or fog days or mountain roads.

EFFECT

HEADLIGHT DESIGN

In addition to providing good lighting effects, the car lights will experience wind, sun, rain, etc. as the vehicle is driving on the road. Therefore, in the face of environmental tests, it is necessary to ensure that the lights will not be affected by the environment. In addition to protecting the rights and interests of consumers, what is more important is to make the lights function normally and exert their effects.

We will provide test videos and simulated images to ensure that you can get the most ideal product results.

In design, in addition to focusing on the effect of light sources, we are also very particular about the shape and material selection to ensure safety and design results.

PROFESSIONAL TECHNICAL

TECHNOLOGY DEVELOPMENT

Appearance and shape design

According to your ideas and concepts, we use 3D stereo simulation to present the appearance and shape of the product in your concept. With the 3D stereo simulation diagram, confirm in advance whether the product appearance and shape conform to your ideas, and accurately present the product prototype in your mind.

Mechanism design

In the design phase of 3D modeling, we use 3D modeling to find errors early and improve products in advance, to detect and solve technical problems that may occur in mass production in the future, so as to shorten the mold development timeline and reduce mold development. The error

Mold flow analysis

In the product development stage, computer simulation analysis is used to evaluate whether the product shape, material characteristics, molding method, etc. are perfect, so as to predict the quality of the product design or mold design in advance and revise the design in time to reduce the waste of experimental time and raw material costs And the risk of development failure.

Optical mirror analysis

We have advanced mirror technology (free-form or multi-reflection) and have passed a number of international regulatory certifications, such as SAE, ECE.

Light shape simulation

We will simulate possible light shapes before actual testing.

Circuit design

Use circuit design software for simulation and analysis. Optimize design efficiency in the design process to ensure that the circuit complies with EMI/EMC and other relevant verification specifications.

Model making

We provide customers with full-size model samples to review and confirm the product’s appearance, material use, quality strength, and assembly accuracy.

TECHNOLOGY DEVELOPMENT

Appearance and shape design

According to your ideas and concepts, we use 3D stereo simulation to present the appearance and shape of the product in your concept. With the 3D stereo simulation diagram, confirm in advance whether the product appearance and shape conform to your ideas, and accurately present the product prototype in your mind.

Mechanism design

In the design phase of 3D modeling, we use 3D modeling to find errors early and improve products in advance, to detect and solve technical problems that may occur in mass production in the future, so as to shorten the mold development timeline and reduce mold development. The error

Mold flow analysis

In the product development stage, computer simulation analysis is used to evaluate whether the product shape, material characteristics, molding method, etc. are perfect, so as to predict the quality of the product design or mold design in advance and revise the design in time to reduce the waste of experimental time and raw material costs And the risk of development failure.

Optical mirror analysis

We have advanced mirror technology (free-form or multi-reflection) and have passed a number of international regulatory certifications, such as SAE, ECE.

Light shape simulation

We will simulate possible light shapes before actual testing.

Circuit design

Use circuit design software for simulation and analysis. Optimize design efficiency in the design process to ensure that the circuit complies with EMI/EMC and other relevant verification specifications.

Model making

We provide customers with full-size model samples to review and confirm the product’s appearance, material use, quality strength, and assembly accuracy.

OEM PROCESS

In order to meet the creative needs of customers and create more value for customers, we have always maintained flexible application and continuous research and development technology. We continue to pay attention to future technological trends and needs, and put into new product development so that our products remain competitive and good quality.

OEM PROCESS

In order to meet the creative needs of customers and create more value for customers, we have always maintained flexible application and continuous research and development technology. We continue to pay attention to future technological trends and needs, and put into new product development so that our products remain competitive and good quality.